-

Abrasive and abrasive products hydraulic press and production lineabrasive products hydraulic press and production line

Our Abrasive and Abrasive Products Hydraulic Press is specifically designed for the precise shaping and forming of grinding tools made from ceramics, diamonds, and other abrasive materials. The press is widely used for manufacturing products such as grinding wheels. The machine body of the hydraulic press comes in two types: the small-tonnage model typically features a three-beam four-column structure, while the large-tonnage heavy-duty press adopts a frame or stacking plate structure. In addition to the hydraulic press, various auxiliary mechanisms are available, including floating devices, rotating material spreaders, mobile carts, external ejection devices, loading and unloading systems, mold assembly and disassembly, and material transportation, all aimed at meeting the requirements of the pressing process and improving production efficiency.

-

Metal Powder Products Forming Hydraulic Press

Our powder products hydraulic press is specifically designed for shaping a wide range of metal powders, including iron-based, copper-based, and various alloy powders. It is widely used in industries such as aerospace, automotive, electronics, appliances, and instrumentation for the production of components like gears, camshafts, bearings, guide rods, and cutting tools. This advanced hydraulic press enables precise and efficient formation of complex powder products, making it a valuable asset in various manufacturing sectors.

-

Vertical Gas Cylinder/Bullet Housing Drawing Production Line

The Vertical Gas Cylinder/Bullet Housing Drawing Production Line is specifically designed for the production of cup-shaped (barrel-shaped) parts with a thick bottom end, such as various containers, gas cylinders, and bullet housings. This production line enables three essential processes: upsetting, punching, and drawing. It includes equipment such as a feeding machine, medium-frequency heating furnace, conveyor belt, feeding robot/mechanical hand, upsetting and punching hydraulic press, dual-station slide table, transfer robot/mechanical hand, drawing hydraulic press, and material transfer system.

-

Gas Cylinder Horizontal Drawing Production Line

The gas cylinder horizontal drawing production line is designed for the stretching forming process of super-long gas cylinders. It adopts a horizontal stretching forming technique, consisting of the line head unit, material loading robot, long-stroke horizontal press, material-retreating mechanism, and line tail unit. This production line offers several advantages such as easy operation, high forming speed, long stretching stroke, and a high level of automation.

-

Gantry Straightening Hydraulic Press for Plates

Our gantry straightening hydraulic press is designed specifically for the straightening and forming processes of steel plates in industries such as aerospace, shipbuilding, and metallurgy. The equipment consists of a movable cylinder head, a mobile gantry frame, and a fixed worktable. With the ability to perform horizontal displacement on both the cylinder head and the gantry frame along the length of the worktable, our gantry straightening hydraulic press ensures precise and thorough plate correction without any blind spots. The main cylinder of the press is equipped with a micro-movement downward function, allowing for accurate plate straightening. Additionally, the worktable is designed with multiple lifting cylinders in the effective plate area, which facilitates the insertion of correction blocks at specific points and also assists in lifting the plates.ifting of the plate.

-

Automatic Gantry Straightening Hydraulic Press for Bar Stock

Our automatic gantry straightening hydraulic press is a complete production line designed to efficiently straighten and correct metal bar stock. It consists of a mobile hydraulic straightening unit, a detection control system (including workpiece straightness detection, workpiece angle rotation detection, straightening point distance detection, and straightening displacement detection), a hydraulic control system, and an electrical control system. This versatile hydraulic press is capable of automating the straightening process for metal bar stock, ensuring superior accuracy and efficiency.

-

Insulation Paperboard Hot Press Forming Production Line

The Insulation Paperboard Hot Press Forming Production Line is a fully automated system consisting of various machines, including the Insulation Paperboard Pre-loader, Paperboard Mounting Machine, Multi-layer Hot Press Machine, Vacuum Suction-based Unloading Machine, and an Automation Electrical Control System. This production line utilizes real-time PLC touchscreen control based on network technology to achieve high precision and fully automated production of insulation paperboard. It enables intelligent manufacturing through online inspection, feedback for closed-loop control, fault diagnosis, and alarm capabilities, ensuring superior quality and efficiency.

The Insulation Paperboard Hot Press Forming Production Line combines advanced technology and precise control to deliver exceptional performance in the manufacturing of insulation paperboard. With automated processes and smart control systems, this production line optimizes efficiency and accuracy, making it ideal for various applications. -

Heavy Duty Single Column Hydraulic Press

The single column hydraulic press adopts a C-type integral body or a C-type frame structure. For large tonnage or large surface single column presses, there are usually cantilever cranes on both sides of the body for loading and unloading workpieces and molds. The C-type structure of the machine body allows for three-sided open operation, making it easy for workpieces to enter and exit, molds to be replaced, and workers to operate.

-

double action deep drawing hydraulic press

Versatile Solution for Deep Drawing Processes

Our double action drawing hydraulic press is specifically designed to meet the requirements of deep drawing processes. It offers exceptional versatility and adaptability, making it suitable for various applications across different industries. With its unique structural features and advanced functionality, this hydraulic press provides outstanding performance and efficiency in deep drawing operations. -

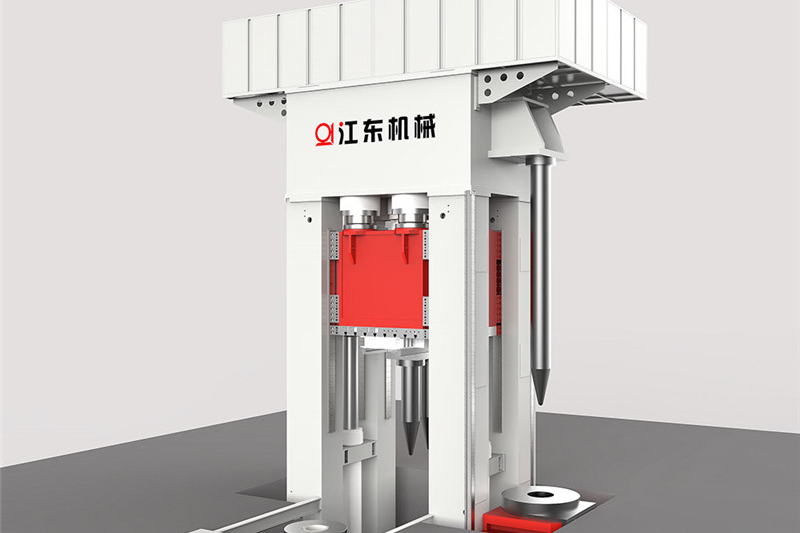

Carbon products hydraulic press

Our carbon products hydraulic press is specifically designed for precise shaping and forming of graphite and carbon-based materials. With a vertical or horizontal structure available, the press can be tailored to the specific type and feeding method of the carbon products. The vertical structure, in particular, offers dual-directional pressing for achieving uniform product density when high consistency is required. Its robust frame or four-column structure ensures stability and durability, while advanced pressure control and position sensing technologies enhance precision and control.